Research Highlights

Current Research Themes

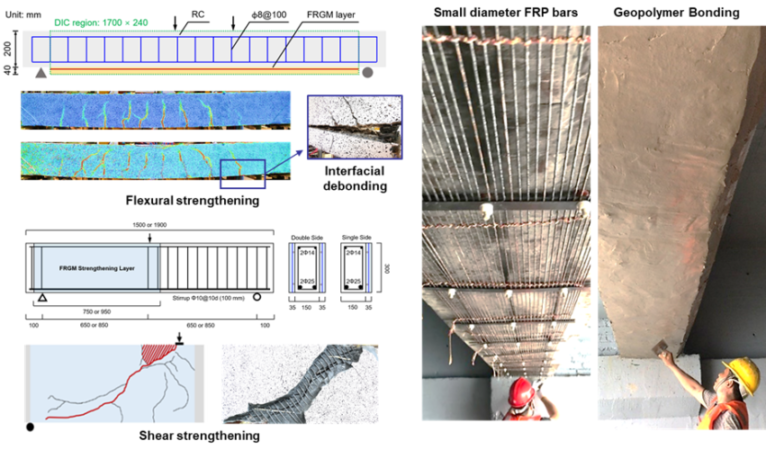

FRP Composites for Construction

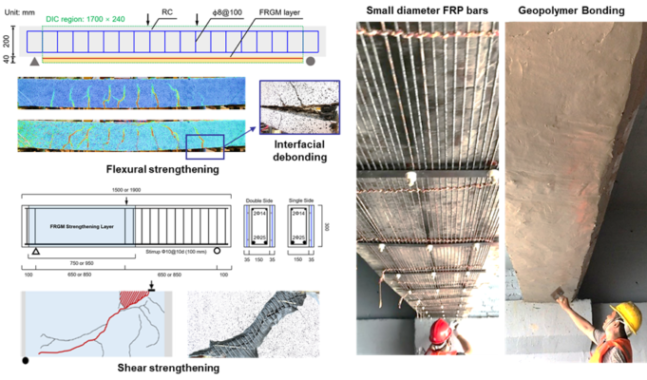

Fiber-reinforced polymer (FRP) composites have been widely used as externally bonded materials to strengthen existing reinforced concrete (RC) structures through research and development over the past few decades. The behaviors of FRP-strengthened RC structures under normal service environments have been extensively studied, especially regarding the mechanisms of FRP-bonded interfaces and FRP-confined concrete. Our recent research mainly focuses on the behavior and modeling of FRP-strengthened RC structures under extreme mechanical (e.g., seismic and impact) and environmental (e.g. moisture, elevated temperature and fire) loadings. We are also exploring the applications of FRP composites for building construction, such as prefabricated sandwich wall panels with FRP as structural reinforcements and shear connectors, to improve the structural and thermal efficiency of building concrete walls, and for corrosion-free marine construction, such as very large floating structures (VLFS).

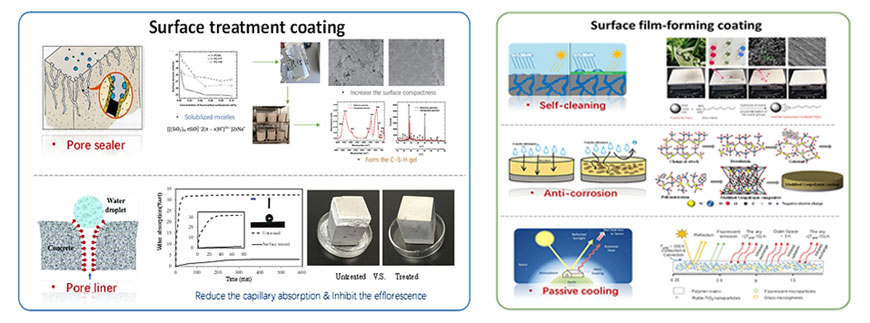

Multi-functional Coatings

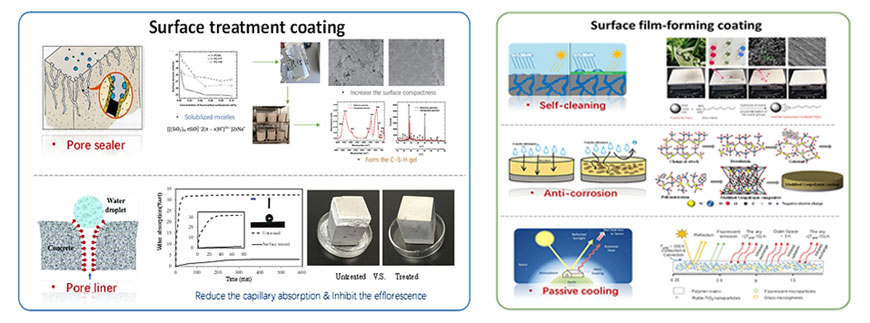

Among the many solutions to improve the durability and energy efficiency of concrete buildings and infrastructures, surface coating is one of the most cost-effective and attractive preventive maintenance technologies. This technology can prevent the ingress of harmful substances (e.g., water, chloride ions, carbon dioxide, sulfate) from external environments that lead to the deterioration of concrete buildings and infrastructures. On the other hand, it can be combined with passive cooling technologies (such as heat insulation, reflection or heat radiation) to reduce the energy consumption of air conditioning required to maintain the indoor human comfort. Our present research is focused on the development of eco-friendly (e.g., waterborne, fully using water as solvent or dispersant) multifunctional building coatings that are featured with the properties of self-cleaning (e.g., super-hydrophobic), anti-corrosion (e.g., labyrinth effect, improving the barrier effect to increase electrochemical resistance) and energy-saving (e.g. passive cooling), to provide innovative solutions for the green and sustainable development of concrete buildings.

Ultrahigh performance fiber-reinforced cementitious composites

In recent years, significant research progress has been made in the development of high-performance fiber-reinforced cementitious materials [e.g., Engineered Cementitious Composite (ECC) and Ultra-High Performance Concrete (UHPC)], which are promising for construction of sustainable concrete infrastructures. ECC shows significant tensile strain-hardening and multiple-cracking characteristics, and UHPC shows ultra-high compressive strength, high tensile strength, and excellent durability. Through the use of high modulus polyethylene (HMPE) fibers and based on micro-mechanic design, our group has successfully developed an ultra-high-performance engineered cementitious composite (UHP-ECC), which combines the properties of strain-hardening, multiple cracking, and ultra-high mechanical strength. UHP-ECC can be reinforced by conventional steel reinforcement or fiber-reinforced polymer (FRP) reinforcement. The combined use of UHP-ECC and FRP is a promising approach to develop a structural component with high strength, durability and ductility. In addition, our efforts also extend to the development of UHP-ECC using seawater and sea-sand directly (i.e., seawater sea-sand UHP-ECC), which can be used in marine construction for improved structural performance, durability and sustainability.

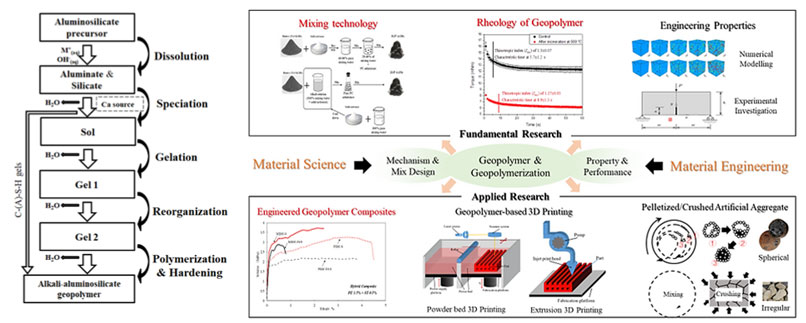

Geopolymer materials and technologies

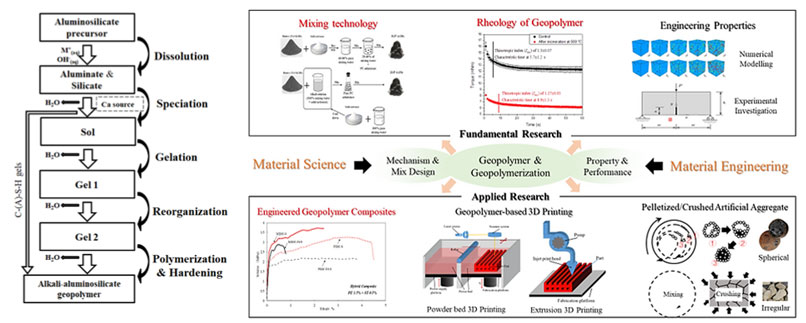

The vast development of infrastructures has occasioned a pronounced increase in the ordinary Portland cement (OPC) consumption worldwide, which causes a heavy burden on the environment. Alkali-activated materials, termed as “geopolymers”, offer an environmentally-friendly toolkit of binders that can replace OPC in specific applications, due to their performance and durability advantages. Our research work is covering both fundamental theories and applied engineering within the context of two types of geopolymers: alkali-aluminosilicate (AAS) geopolymer and silico-aluminophosphate (SAP) geopolymer. Our fundamental research is focusing on mixing method of geopolymer binders, their engineering properties and applications such as manufacturing functionalized artificial aggregates and repair and strengthening of reinforced concrete structures.

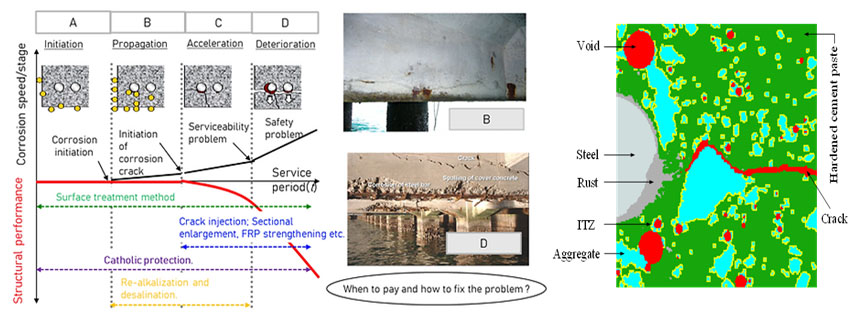

Durability and life cycle maintenance

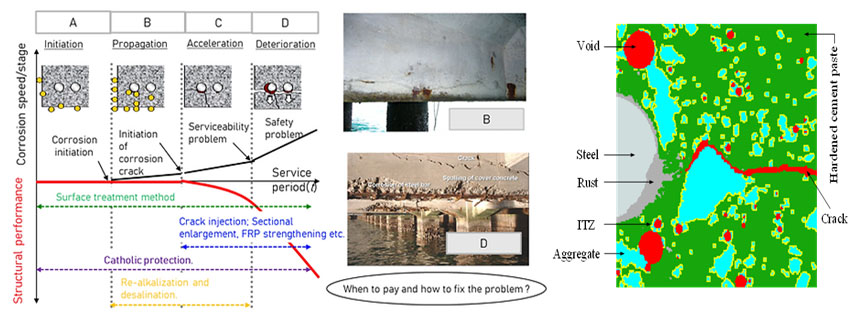

The corrosion of steel in concrete structures under severe service conditions (e.g. coastal and marine environments) is by far the largest contributor to the massive infrastructure deterioration problem around the world. Our group devotes to developing a predictive tool for the corrosion-induced degradation of marine concrete structures with different types of reinforcement and to developing optimal corrosion-prevention and maintenance techniques for different corrosion stages of marine concrete structures. Our very recent research efforts include: meso-scale modeling of chloride ingress in concrete on the basis of the X-ray microcomputed tomography (X-ray μCT), monitoring of corrosion-induced cracks in high performance fiber-reinforced cementitious composites, electro-chemical corrosion mechanisms of different types of steel reinforcement in cementitious matrices, and long-term exposure tests of concrete structures in accelerated and in-situ marine environments.

PhD Dissertations

WENG Kefan

Shear behavior of high-performance reinforced concrete beams enabled by FRP and UHPC

2024

TENG Jincheng

Behavior and modeling of sand-filled GFRP pile-wall system in reclamation engineering

2023

HAO Zhihao

Durability of FRP reinforced seawater seasand cocnfrete beams and FRP-strengthened reinforced concrete beams

2023

ZHU Jixiang

Development of FRP-reinforced UHS-ECC composite system for performance enhancement of RC beams

2023

YANG Ning

Development of multifunctional geopolymer coatings for performance upgrading of civil engineering structures

2023

QIAN Lanping

Development of artificial aggregates from wastes and by-products for sustainable construction

2023

KUMAR Sushil

In-plane behavior of BFRP grid reinforced geopolymer concrete sandwich wall panels

2023

XU Lingyu

High-strength engineered cementitious composites incorporating artificial geopolymer fine aggregates

2022

GUO Dong

Effect of temperature variation on the interfacial debonding mechanisms of FRP-strengthened steel beams

2022

PENG Kaidi

Strengthening of reinforced concrete beam using geopolymer bonded mini CFRP bar

2022

YAZAN Alrefaei

Fresh and hardened properties of ambient cured one-part alkali-activated pastes along with superplasticizers

2021

YU Kequan

Ultra-high performance engineered cementitious composites (UHP-ECC) :mechanical behavior of material and structural members

2019

HUANG Junqi

Structural Performance of Precast Reinforced Geopolymer Concrete Sandwich Panels Enabled by FRP connectors

2019

WANG Yanshuai

Influences of metal ions on formation of silico-aluminophosphate geopolymer

2018

DING Yao

Experimental study on fracture properties of alkali-activated concrete

2017

BAI Yulei

Behavior and modeling of RC columns confined with large-rupture strain FRP composites

2014

GAO Wanyang

Fire resistance of FRP-strengthened RC beams : numerical simulation and performance-based design

2013